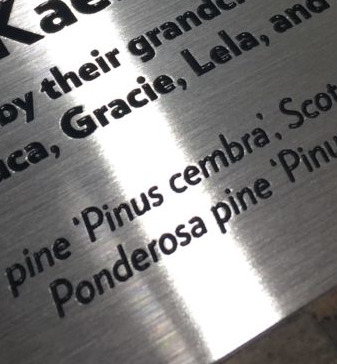

etched and painted metal

(There's a separate page for less durable labels and signs.)

TODO

— Add a table of contents here, like I did at the PCL techniques page.

Signs often have two or three layers — a base material to ensure rigidity, an ink/pigment/paint layer for the lettering, and sometimes† a clear topcoat to improve the sign's durability and wear-resistance.

A label maker creates a strip of plastic with lettering that's easy to read and wear-resistant, all at once. So that's the easiest option, when it suits your needs.

I like the Bluetooth versions of label makers because they let you use your phone's touchscreen as a user interface. Just be sure to read the app reviews before buying the hardware — some manufacturers know a lot about producing good hardware, but very little about producing good software, because those are very different skill sets.

If you don't want it to look like it came from a label maker, clear labels do exist, and you can even cut around the letters.

"Industrial" / "jobsite" versions of label makers do exist. Brady Corporation is one company that makes them. [Brady labels] [Brady label makers] (Ctrl-F for "label properties" on that labels link, they've got some interesting specialty products)

TODO

— Maybe break this out into its own page, so I can tackle that fact that most basic label printers don't produce archival-quality labels? [1] [2]

PVC foam board is frequently used for rigid outdoor signs. (Google images)

Very large signs (AKA billboards) are printed on PVC or polyethylene. (Then the otherwise floppy sign is put under a lot of tension to ensure it lays flat.)

TODO

— Mention sharpies, paint markers, and stencils.

Some professionals hand-letter signs with a brush [2] [3], and that some of those same skills might work with brush pens and ink pens as well.

For especially small text, there are fewer options:

TODO— Find that advice that I've seen from D&D miniature painters about what brushes they prefer, and any brush techniques they recommend, for super-tiny brush strokes.

This isn't always necessary,† for example if you're using a more durable surface with painted lettering. However, it makes the lettering more durable, and is especially important with paper-based lettering.

The easiest solution is to put some adhesive plastic film over it — adhesive film won't make the pigment run/smear, so you don't have to wait days for the pigment to dry before you can apply the clearcoat. I really like to use adhesive lamination sheets, but for smaller labels you could use regular packing tape, and for larger use adhesive lamination rolls.

Of course, traditional lamination works too.

There are various ways to seal acrylic paints [2] and oil paints.

TODO

— Find the URLs that mention that for anything but adhesive film, that it's usually critical that the lettering be 99% dry, otherwise you risk smearing the lettering. For painted lettering, this usually means waiting several days, and mention that oil paints do take longer than acrylic paints to dry.

I'm going to focus on paper-based signs for a minute, just because they're so easy to make — almost everyone has access to a printer.

Ways to make paper-based signs more durable:

Most home printers are capable of printing on other materials as well, such as:

All of the above are available in a variety of colors — cardstock, transparency film, and vellum paper.

It's possible to print a mirror-image onto transparent or translucent material, and then install the transparent material back-side out. (TODO

— This part may be unclear, so draw a quick SVG to explain what I mean?) This way the transparent/translucent material functions to protect the ink from abrasion and water damage.

Different methods for etching/engraving/embossing/stamping:

How to paint the engraved/embossed letters:

TODO— Talk about methods for leaving only the recessed areas painted, and methods for leaving only the surface-level areas painted.

Print your own at home:

TODO— read about using "Press-N-Peel" PCB film to do steel etching [1] [2] [3]

Hand-cut stencils at home:

Tools that are sometimes available at a local hackerspace/makerspace:

Online services that can make custom stencils:

If you're writing a message, it's also possible to buy alphabet stencils and paint the letters on, one-by-one.

There's a long tradition of people painting signs completely freehand, with nothing more than a few guidelines penciled in.

Screen printing [video introduction] is a very versatile technique that works on a wide variety of surfaces, including metal, wood, glass, PVC foam board, acrylic, and vinyl, among others.

But screen printing at home is a big topic that's beyond the scope of this article, so check out <screen printing at home> on YouTube instead.

If you live near Chicago, there are TWO community screen-printing studios [1] [2] that can get you up to speed faster, and it's possible that others exist in other cities.

TODO

, expand on these:

For high-heat applications, high-heat clear epoxies are a good option for a clearcoat.

For outdoor / weatherproof uses:

† Artists often debate about whether fixatives or sealants should be used on top of their pieces of art. Of course, sign makers are interested in practical usability in a way that artists aren't, however, some (many?) real-world signs aren't protected with a top coat.