- Only predrilled, no pre-etching (solid coper outside of holes). Most likely you chemically etch the board per above (though it may be a little less dense than above due to extra holes, and is more expensive)

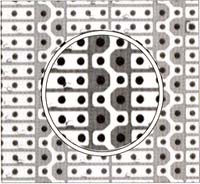

- stripboard, where strips need to be severed mechanically (often requires some point-to-point wires, sometimes many)

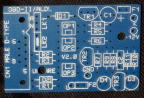

- example layout

- a number of examples

- VCAD, GPL'd stripboard layout

- Various other patterns that are variations on stripboard, with fewer traces requiring likely no severing/etching, though it's less dense and harder to lay out than veroboard.

- Wire-wrap

- Solder leads directly together (eg. another "ugly prototyping")

- Scotchflex (?? ask Don Estabrook...)

Note that in some cases, this may be one of your only options (eg. here or here)